Complex sensor technology components

Zetec ranks among the leading manufacturers of components and assemblies pertaining to sensor technology, optoelectronics and measuring or control technology. As a partner of virtually all sensor technology manufacturers, Zetec has consequently acquired a wide-ranging expertise over the last 30 years. This expertise has been key in Zetec developing a reputation as an experienced and complex system partner and problem solver when it comes to highly precise turned and milled parts. We know what it takes to manufacture precision parts for these key industries and impress with a large variety of parts boasting a wide range of dimensions, materials, geometries and surfaces. This extensive experience has already allowed us make your production more efficient right from the design phase. We will supply you with the perfect rotated or milled parts for your sensor technology components.

Zetec’s range of sensor technology products

|

|

Adapters/plug-in connectors

manufactured with a special mould

finest turned surface

Special piercing contour

Fine thread

Material

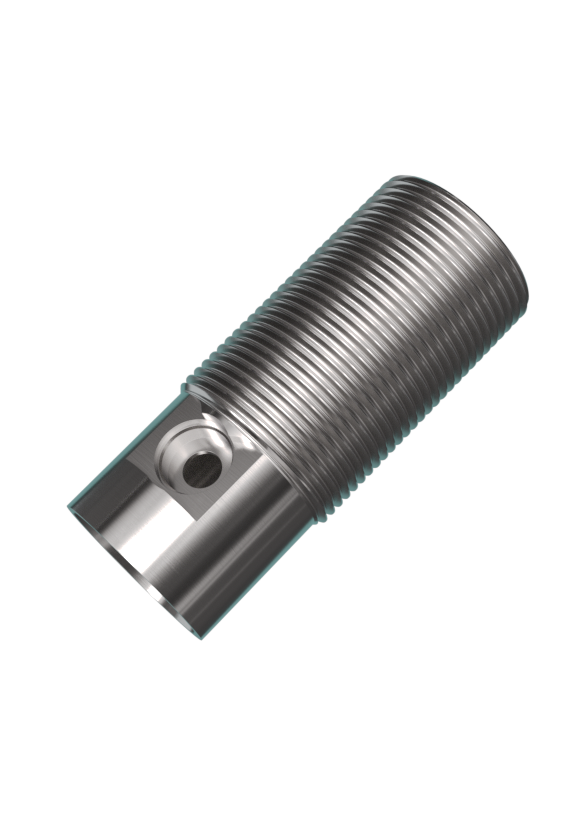

Threaded sleeve

extremely thin-walled fitting

Thin-walled

Fine thread

Multi-stage cross machining

Exactly positioned transition

Milling

Material

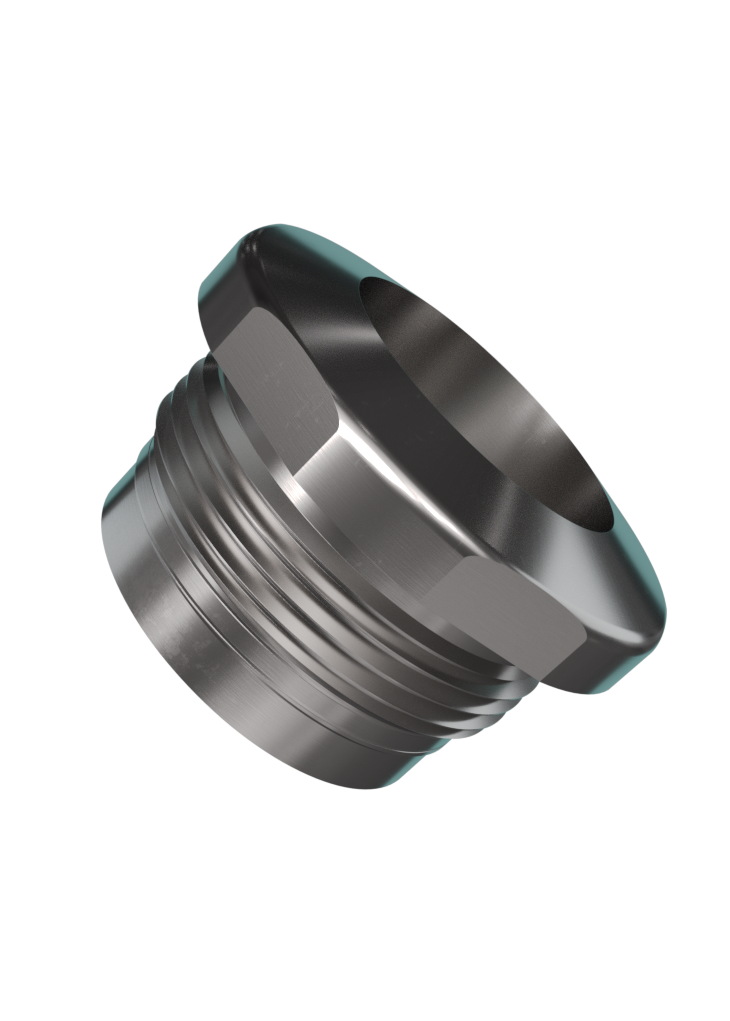

Threaded bush

special bayonet lock for a secure plug-in connection

Bayonet catch

Sealing surface

Material

Fine thread

Sleeve

Surface

Wall thickness

Fine thread

Fitting dimension

Material

Diameter

LED drill holes

Fastening nut

complete machining on the turning machine

Fit

interrupted thread

Visible surface

Material

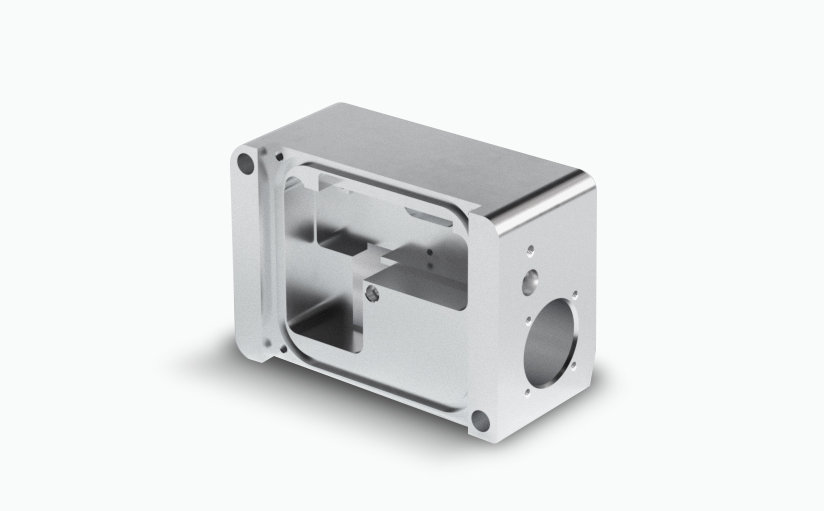

Housing

Milled part

Fine thread

Breakthroughs

deep pockets

Materials

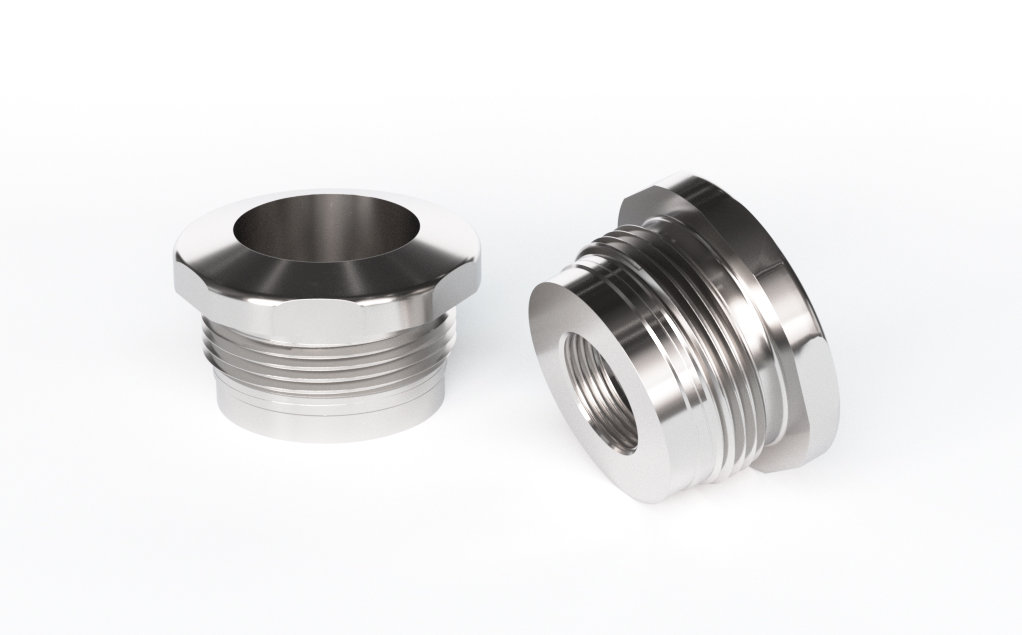

Plug

Plug

Fine thread

Visible surface

Shape stitch

Internal thread

Width across flats milled

Adapter

Boreholes

Blind hole thread

Width across flats milled

Material

Sealing surface

Sleeve

Plug

Housing

Complex Geometry

Complete machining on the lathe

Materials

Shock contour

Adapter (square)

Complex inner contour

Cubic shape

Material

Threaded sleeve

Visible surface

Milling

Fine thread

Material

Device plug-in connection

Groove

Bayonet

Material

Width across flats

Precision for sensor technology

Here you can find a selection of sensor products, sensor technology components and assemblies that are representative of our high precision demands.

Medical technology

Mechanical engineering

Additional industries

Get us involved in your tasks.

In an ideal scenario, we will already be involved in the development and design phase of challenging precision parts. We provide you with highly precise, efficient solutions to any problem, and ensure they get to you right on time. We look forward to taking on whatever challenges you may have!

Zetec Zerspanungstechnik GmbH

Daimlerstraße 9

78559 Gosheim

Germany

Telephone: +49 7426 5298-0

Telefax: +49 7426 5298-78

Mail info@zetec.de